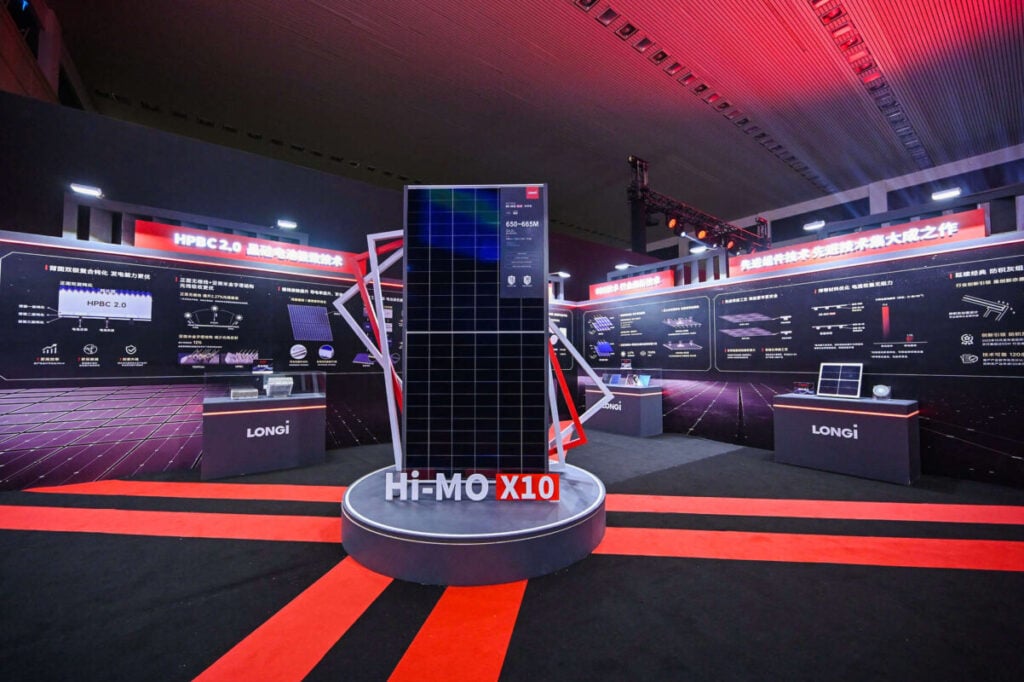

LONGi introduced its next-generation back contact modules earlier in October using its proprietary HPBC 2.0 cell technology with a mass production output of 670W. It claims up to 24.8% module efficiency, which, the company claims, would break the global module mass production efficiency record for back contact modules. Using the popular module size of 2,382mm x 1,134mm, it outperforms conventional TOPCon modules by 30W.

Aimed at the distributed generation segment, the Hi-MO X10 is designed to maximise reliability, cost-effectiveness, and long-term performance.

Key Hi-MO X10 parameters:

1. The use of high-quality n-type TaiRay silicon wafers results in high resistance distribution, good impurity gettering, and stronger mechanical properties—all thanks to an improved Czochralski process. According to LONGi, the proprietary TaiRay wafer solves the long-standing challenges of silicon wafer limitations. With improved resistance distribution, fewer impurities and a remarkable 16% increase in break resistance, this wafer is said to be a key driver of the Hi-MO X10’s high performance.

2. The power temperature coefficient of -0.26%/°C delivers a 0.03% improvement over TOPCon modules and ensures reliable performance in hot and humid climates, according to the company. It features 1% degradation in the first year and linearly decays by 0.35% for the remaining 29 years based on its 30-year product power warranty.

3. Its zero busbar (0BB) structure means that the modules have no busbar on the front and in the back. By connecting the ribbons directly to the fingers, the energy transfer distance is reduced by 6.5%, adding an extra 5W to the module’s power output. Precision laser etching and advanced, highly transparent insulating materials further enhance performance by reducing the risk of leakage and improving light absorption.

4. A new multi-layer structure with three components: a light absorption layer with an anti-reflective film that improves short-circuit current by 2.25% and reduces short-wave reflections by over 12%, ensuring more sunlight is effectively captured; a photovoltaic conversion layer that utilises a proprietary “Bipolar Hybrid Passivation Technology” that increases the open-circuit voltage by 15mV to 745mV and significantly reduces UV-induced degradation while increasing long-term efficiency; and an electrical transmission layer that includes a “Soft Breakdown Design+” and bipolar low resistance passivation contacts. The latter is said to reduce shading power loss by more than 70% and reduce hotspot temperatures by 28%.

Back contact considered solar module technology for the future

The company’s commitment to improving back contact technology is rooted in the beliefs of LONGi Chairman Baoshen Zhong, who last year repeatedly expressed his confidence in the future of BC technology. “We firmly believe that back contact technology will become the dominant force in crystalline silicon cells, including both bifacial and monofacial designs,” he said in a company statement.

In May 2024, LONGi announced a world record for photovoltaic conversion efficiency at 27.3% for its new silicon heterojunction back-contact (HBC) solar cells certified by the Institute for Solar Energy Research Hamelin (ISFH). On 24 October, the company announced another world record efficiency of 25.4% for crystalline silicon solar modules based on its HPBC 2.0 cell platform. The efficiency results were certified by the German research institute Fraunhofer ISE. With this record, LONGi declared that it has broken the 36-year monopoly of overseas PV brands.

LONGi’s UK & Ireland General Manager Ross Kent stated that the evolved Hi-MO X10’s technology and design would deliver outstanding reliability with minimal degradation over time, ensuring long-lasting performance. Levelized Cost of Energy (LCOE) would be significantly lowered for customers. According to LONGi, the Hi-MO X10 stands as a beacon of superior efficiency.

LONGi says it has upgraded HPBC 1.0 to HPBC 2.0 in two years, with a cumulative investment of more than RMB 2 billion in R&D efforts and a high-level R&D team of more than 1,000 people. It now boasts nearly 200 BC technology patents.

In Europe, the X10 will be phased in from the fourth quarter of 2024, with mass production on a GW scale planned for the first quarter of 2025.

Investing in wafer improvement benefits the entire PV industry

LONGi claims that its proprietary product, the TaiRay wafer, addresses and solves the persistent problems associated with the traditional limitations of silicon wafers. These limitations could include factors such as wafer thickness, material defects or manufacturing inefficiencies that have historically hindered the performance and cost-effectiveness of silicon wafers in solar cells. In essence, the TaiRay wafer is said to be an innovative solution that overcomes these technical barriers.

The M11 TaiRay wafer size is said to reduce industrial chain costs, engineering costs, and module transportation costs due to improved container utilization during transportation, and balance of system (BOS) costs. Downstream risks are also said to be reduced. For example, the 72-cell version of the X10 can reduce transportation costs by $0.61/kW compared to the previous Hi-MO X6 module and improve 40HC container utilization by 4.4% to achieve 98.5% container utilization, the company stated.

As a result of the performance increase, the balance of system (BOS) cost on the system installation side is also reduced by 3.57% (approximately $4.16/kW) compared to the equivalent mainstream power classes. Customer revenue is said to be increased compared to the use of 210R wafer-based modules. Ross Kent commented: “The X10 and its second generation of back contact technology HPBC 2.0 represents a significant upgrade to the existing back contact technology route and is yet another example of how LONGi embodies its customer-centric approach to delivering maximum customer value.”