Scientists at the University of Oxford have today (9 August) revealed a breakthrough in solar PV technology via an ultra-thin material that can be applied to “almost any building” and deliver over 27% conversion efficiency.

The Oxford scientists have described the new thin-film perovskite material, which uses a multi-junction approach, as a means to generate increasing amounts of solar electricity without the need for silicon-based solar modules.

“During just five years experimenting with our stacking or multi-junction approach, we have raised power conversion efficiency from around 6% to over 27%, close to the limits of what single-layer photovoltaics can achieve today,’ said Dr Shuaifeng Hu, post-doctoral fellow at Oxford University Physics.

“We believe that, over time, this approach could enable the photovoltaic devices to achieve far greater efficiencies, exceeding 45%.”

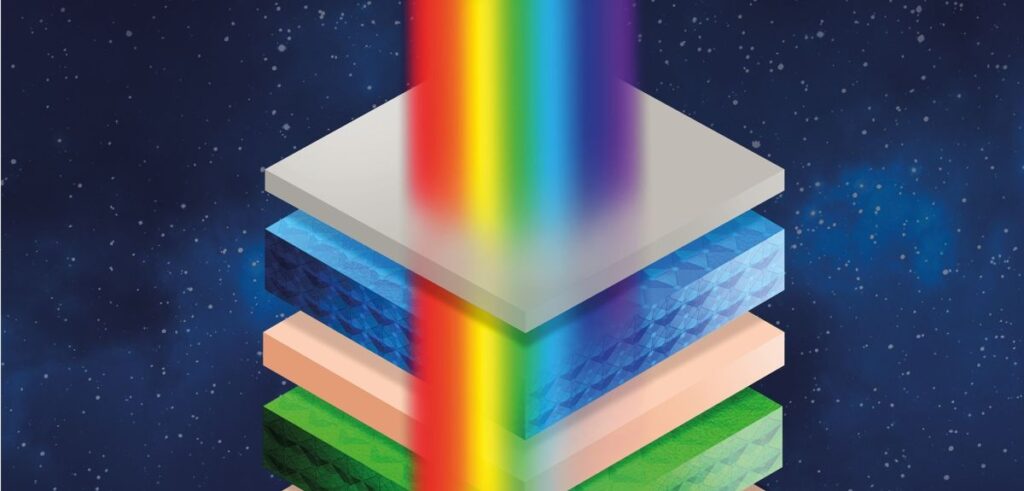

The technology stacks multiple light-absorbing layers into one solar cell, harnessing a more comprehensive range of the light spectrum and allowing more power to be generated from the same amount of sunlight.

Oxford University said that contemporary solar modules’ energy efficiency levels stand at around 22%. Thus, with greater time and resources allocated to the new technology, it could contribute to the global energy transition as it grows more efficient.

The technology brings a new level of innovation with its thinness. At just over one micron thick, it is nearly 150 times thinner than a silicon wafer.

Unlike current photovoltaics, which are typically applied to silicon panels, this technology can be used on almost any surface. The scientists believe that this approach will further reduce the cost of solar energy and help establish it as the most sustainable form of renewable energy.

Japan’s National Institute of Advanced Industrial Science and Technology (AIST) gave its certification before publication of the researchers’ scientific study later this year.

‘By using new materials that can be applied as a coating, we’ve shown that we can replicate and outperform silicon while also gaining flexibility. This is important because it promises more solar power without the need for so many silicon-based panels or specially-built solar farms,’ said Dr Junke Wang, postdoc fellow at Oxford University Physics.

The scientists added that further breakthroughs promise additional cost savings as new materials, like thin-film perovskite, reduce the need for silicon panels and purpose-built solar farms.

Oxford PV talks perovskites suitability for utility-scale solar

Oxford PV, a a UK company spun out of Oxford University Physics in 2010, recently spoke to our sister site PV Tech Premium about the use of perovskite technology and its suitability for utility-scale solar projects.

CEO David Ward argued that the future of solar PV as the lowest cost source of energy lies with silicon-perovskite tandem cells of the type Oxford PV is working to commercialise, beginning with niche, high-value applications like aerospace.

“We expect meaningful scale within that marketplace in 2025,” Ward said. “We’re strategically valuable [in the specialised market], not just on an LCOE-basis like at utility-scale.”

Ward added that Oxford PV would then look to enter the residential market in 2026, “and then during 2026 and into 2027 is when we’ll have the high volume manufacturing up and running (we hope) and that’s our main entry into utility-scale.”

In addition to its new manufacturing facility, based in Germany’s Brandenburg, Ward also touched upon the topic of solar cell degradation.

Ward said that Oxford PV is “comfortable” with its position regarding degradation: “It matches the customer requirements, they’re really happy to take the product in the current form.”

“Our first shipments are going out in a couple of months. They [the customers] really want to get access to the technology and the modules in the real world to go and test them, because what they want is access to the gigawatt scale of this stuff.”